Basic Info.

Product Description

In Motion Checkweigher

The In Motion Checkweigher is a conveyor belt scale that can be used in any industrial environment. The checkweigher measures weight with no human intervention, making it ideal for use in factories, warehouses, and other manufacturing facilities where accuracy is critical. This model also features an auto-stop feature that prevents overload and overloading of the system.

InMotion Industrial Checkweigher Conveyor Belt Scales are an ideal solution for on-the-go weighing of materials. These scales are designed to work with a wide range of materials, from materials that are light and easy to move to heavy, bulky items. The scales have a high speed reading, which allows for fast weighing of large volumes of material.

The InMotion industrial checkweighers have a durable design that is easy to maintain and clean. They are made from durable polycarbonate plastic and stainless steel, which makes them resistant to corrosion and rust. The scale wheels are mounted on a rigid frame that can be easily detached so they can be cleaned or repaired.

InMotion Industrial Checkweigher Conveyor Belt Scales

Industrial checkweighers are used in many areas of industry to ensure that materials are being weighed accurately. The InMotion Industrial Checkweigher is an ideal solution for any application where precise weight measurement is required. This checkweigher can be used to weigh large amounts of material at once, or it can be used one piece at a time, allowing you to adjust the scale's position as needed. The built-in scale includes a moveable measuring wheel that can be adjusted according to your specific needs. If you need more than one weighing station, they can be linked together via our optional network connector cable.

Our industrial checkweighers are available in either stand-alone models (which can be placed inside a machine) or integrated models (which mount on top of other equipment).

You can use checkweighers in a wide range of industries and applications. Some products are used in order to identify overweight or underweight packaging. Other products are used to verify process performance and measure efficiency in production lines.

In the print industry checkweighers can capture production totals by day/shift, batch, or production runs.

The food, drink, and pharmaceutical processing sectors use checkweighers for information such as outs of tolerance conditions for regulatory authorities. Checkweigher suppliers indicate whether products are compliant with the reporting standards of the Food and Drug Administration and U.S. Department of Agriculture.

Metal detector general specification

| Detected products Height | 80 | 120 | 80 | 100 | 120 | 150 | 200 |

| Detected products Width | 300 | 300 | 400 | 400 | 400 | 400 | 400 |

| Belt Width | 250 | 250 | 350 | 350 | 350 | 350 | 350 |

| Belt length | 1500 | ||||||

Detector sensitivity | Feф0.5 | FeФ0.8 | FeФ0.6 | FeФ0.7 | FeФ0.8 | FeФ0.8 | FeФ1.0 |

| SUSф1.0 | SUSФ1.5 | SUSФ1.0 | SUSФ1.2 | SUSФ1.5 | SUSФ2.0 | SUSФ2.3 | |

| N-Feф0.8 | N-FeФ1.0 | N-FeФ0.8 | N-FeФ1.0 | N-FeФ1.2 | N-FeФ1.5 | N-FeФ1.5 | |

| Speed of belt | 27M/min (can adjust 5-40 M/min) | ||||||

| Load ability | 20KG | ||||||

| Count | 100 | ||||||

| Reject Ways | Sound and light alarm with belt stoped ;(when has auto-reject system ,belt continue and rejecting the goods ) | ||||||

| Application | Non-package ,plastic package ,paper bag or box (non-metallic) product | ||||||

| Work Environment | Temperature -10ºC-40ºC ,relative humility 30-90% | ||||||

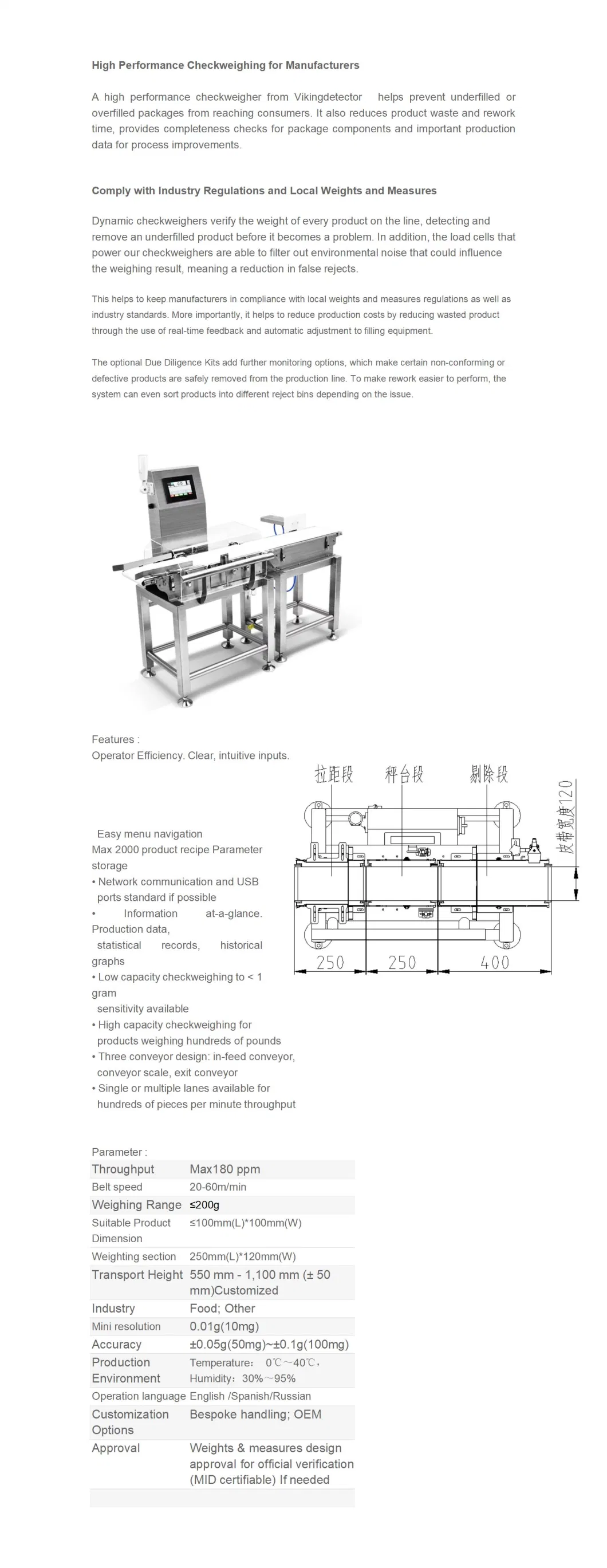

High Performance Checkweighing for Manufacturers

A high performance checkweigher from Vikingdetector helps prevent underfilled or overfilled packages from reaching consumers. It also reduces product waste and rework time, provides completeness checks for package components and important production data for process improvements.

Comply with Industry Regulations and Local Weights and Measures

Dynamic checkweighers verify the weight of every product on the line, detecting and remove an underfilled product before it becomes a problem. In addition, the load cells that power our checkweighers are able to filter out environmental noise that could influence the weighing result, meaning a reduction in false rejects.This helps to keep manufacturers in compliance with local weights and measures regulations as well as industry standards. More importantly, it helps to reduce production costs by reducing wasted product through the use of real-time feedback and automatic adjustment to filling equipment.

The optional Due Diligence Kits add further monitoring options, which make certain non-conforming or defective products are safely removed from the production line. To make rework easier to perform, the system can even sort products into different reject bins depending on the issue.

| Throughput | Max180 ppm |

| Belt speed | 20-60m/min |

| Weighing Range | ≤200g |

| Suitable Product Dimension | ≤100mm(L)*100mm(W) |

| Weighting section | 250mm(L)*120mm(W) |

| Transport Height | 550 mm - 1,100 mm (± 50 mm)Customized |

| Industry | Food; Other |

| Mini resolution | 0.01g(10mg) |

| Accuracy | ±0.05g(50mg)~±0.1g(100mg) |

| Production Environment | Temperature: 0ºC~40ºC,Humidity:30%~95% |

| Operation language | English /Spanish/Russian |

| Customization Options | Bespoke handling; OEM |

| Approval | Weights & measures design approval for official verification (MID certifiable) If needed |

Suitable for